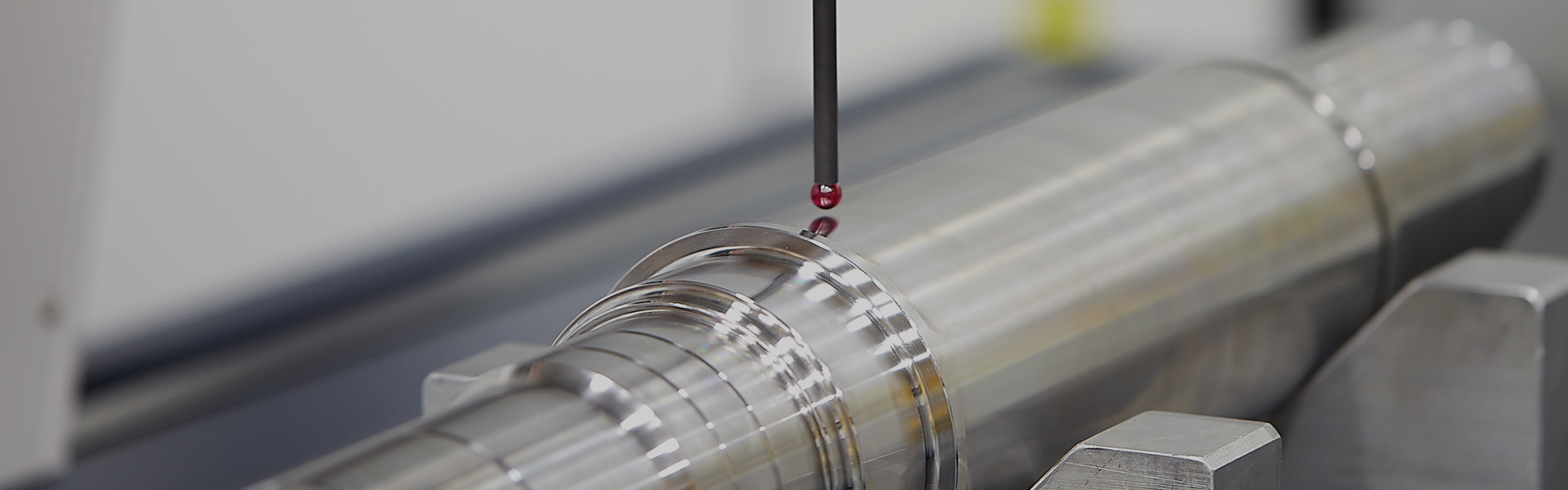

主軸回轉精度測試

Spindle rotation accuracy testing

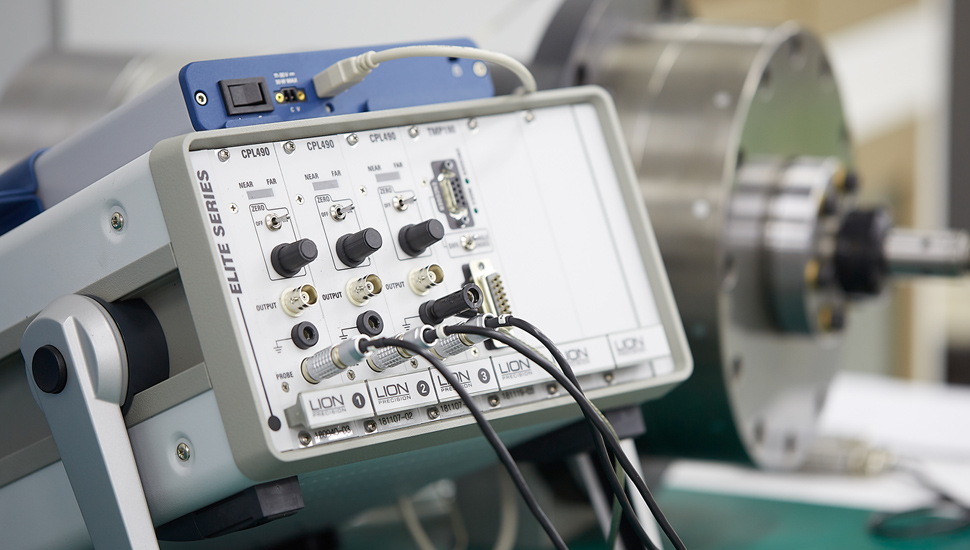

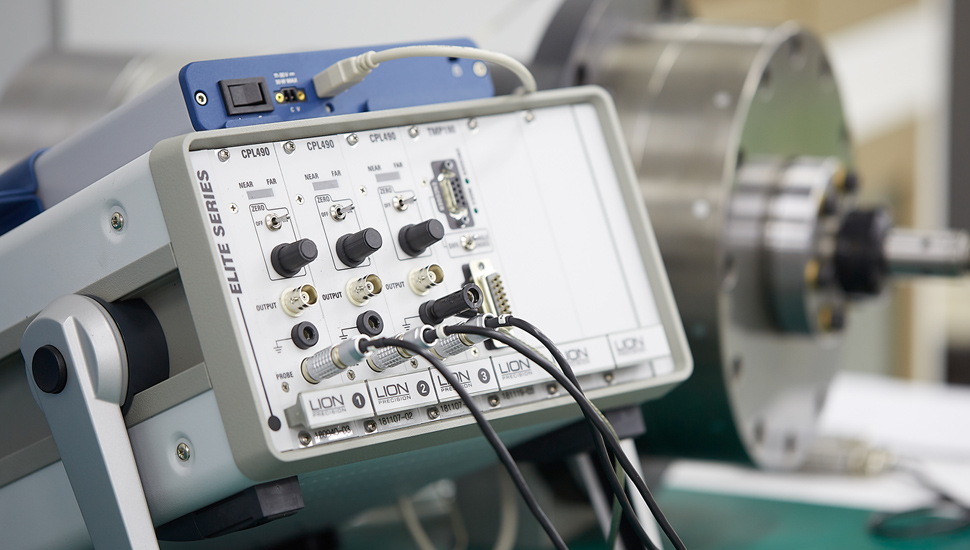

主軸系統(tǒng)動態(tài)特性測試

Spindle system dynamic characteristics testing

主軸回轉精度測試

Spindle rotation accuracy testing

主軸系統(tǒng)動態(tài)特性測試

Spindle system dynamic characteristics testing